CNC plastic machining is an ideal method for meeting strict requirements in shape, precision, and product durability. By applying advanced computer numerical control (CNC) technology, the process ensures high consistency, productivity, and minimal error—helping businesses save both inspection time and production costs.

What Is CNC Plastic Machining?

CNC plastic machining is a mechanical processing method that uses computer-controlled tools (Computer Numerical Control) to shape and cut plastic materials based on digital technical drawings. Unlike manual machining, which relies heavily on operator skill, CNC offers superior accuracy, stable speed, and easy reprogramming for mass production or design changes. This method is well-suited for both intricate one-off prototypes and large-scale industrial production.

CNC plastic machining is a method that uses computer-controlled machine tools to shape and cut plastic materials.

Vì sao doanh nghiệp nên chọn gia công CNC cho sản phẩm nhựa?

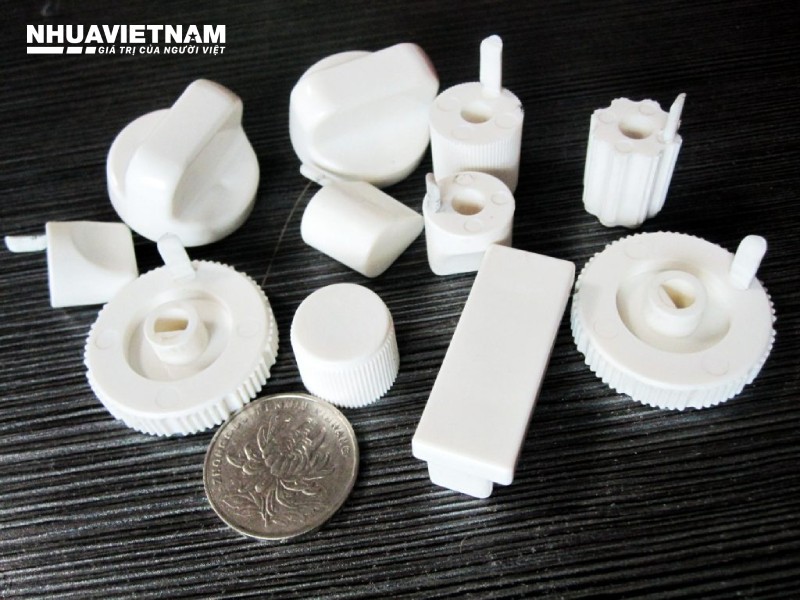

This solution CNC plastic machining include offers several outstanding advantages. Most notably, it delivers high precision with tolerances as tight as ±0.05 mm. It also ensures excellent repeatability, so every part produced maintains consistent dimensions and quality.

In addition, CNC machines can handle complex geometries that are impossible to create by hand or with traditional methods. Engineering plastics such as POM, PP, PVC, PE, PC, PA6, PEEK, and PTFE can all be machined with ease, without warping or compromising structural integrity.

Ứng dụng thực tế của gia công CNC nhựa trong sản xuất

Industries that benefit significantly from CNC plastic machining include:

- Medical equipment: Handles, connectors, and chip holders requiring smooth, burr-free surfaces and hygienic finishes.

- Automotive: ECU housings, structural brackets, and aerodynamic parts needing heat resistance and dimensional stability.

- Automation and industrial machinery: Sliders, grippers, and component frames that must be vibration-free and assembly-ready.

- Electronics: Insulating panels, circuit boards, and chip housings requiring tight tolerances and strong antistatic performance.

CNC plastic machining is applied across a wide range of industries.

Tiêu chí lựa chọn đối tác gia công CNC nhựa uy tín

For manufacturers, selecting a CNC plastic machining include is not just about outsourcing—it’s about choosing a long-term strategic technical partner. A trusted supplier should offer:

- Advanced technology and equipment: 3- to 5-axis CNC systems with CAD/CAM programming capabilities.

- Quality control expertise: CMM measuring tools, tensile/compression testing, surface roughness checks, and ISO-standard tolerance inspections.

- Skilled engineering team: Technicians experienced in handling various plastics and selecting optimal cutting speeds and tooling.

- Production capacity: Ability to fulfill large-volume orders reliably without disrupting the client’s timelines.

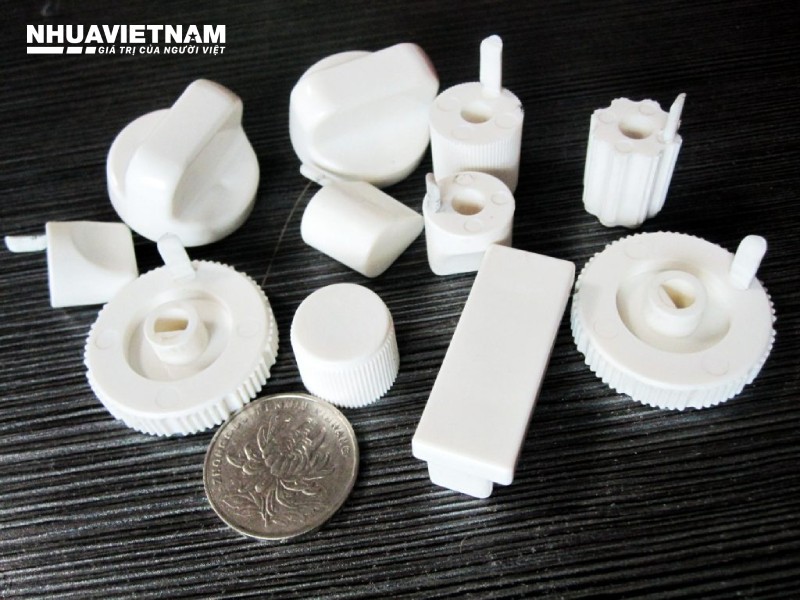

Nhựa Việt Nam – Đối tác gia công CNC nhựa chuẩn công nghiệp

Nhua Viet Nam has heavily invested in state-of-the-art CNC plastic machining include and ISO-certified quality management systems to meet the demands of domestic and international clients in engineering plastics. Our factory operates 24/7 and can fulfill large-scale orders of up to 5 million units, often delivering 5–10 days ahead of schedule—even for demanding markets like Europe and North America.

Our engineering team is well-trained and constantly updated with the latest technologies, ensuring smooth handling of all plastic types. With a focus on sustainable development, Nhua Viet Nam goes beyond machining—we collaborate with clients to optimize design, refine production processes, and enhance overall competitiveness.

Nhua Viet Nam is a trusted industrial-grade partner in CNC plastic machining.

Vì sao nên chọn Nhựa Việt Nam cho dịch vụ gia công CNC nhựa?

Nhua Viet Nam operates modern CNC plastic machining include integrated with flexible CAD/CAM programming, allowing precise processing of engineering plastics with extremely low tolerances. Every product undergoes strict quality checks from raw materials to finished goods, thanks to advanced measuring equipment and a team of experienced technicians.

Beyond production capacity, we support clients with design consultation, model refinement, and cost optimization—ensuring each CNC plastic part meets the highest technical and commercial standards. That’s why many industrial companies have chosen Nhua Viet Nam as a long-term strategic partner for scaling production and improving product quality.

Conclusion

CNC plastic machining plays a vital role in the digital transformation of manufacturing, where speed, precision, and cost-efficiency are paramount. Businesses need partners with comprehensive capabilities—from technology and talent to global production mindset.

With strong technical foundations and high-volume processing capabilities, Nhua Viet Nam delivers a complete solution for companies seeking world-class CNC plastic machining services.

Contact Information

- Hotline: +84 886 723 131

- Email: info@vnplastic.vn

- Address: No. 56, Street 455, Group 4, Hoi Thanh Hamlet, Binh My Commune, Ho Chi Minh City.