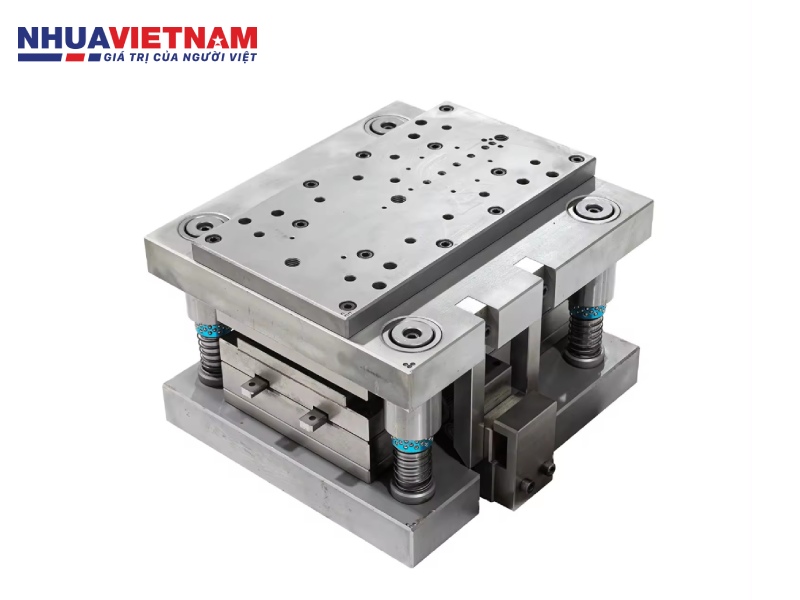

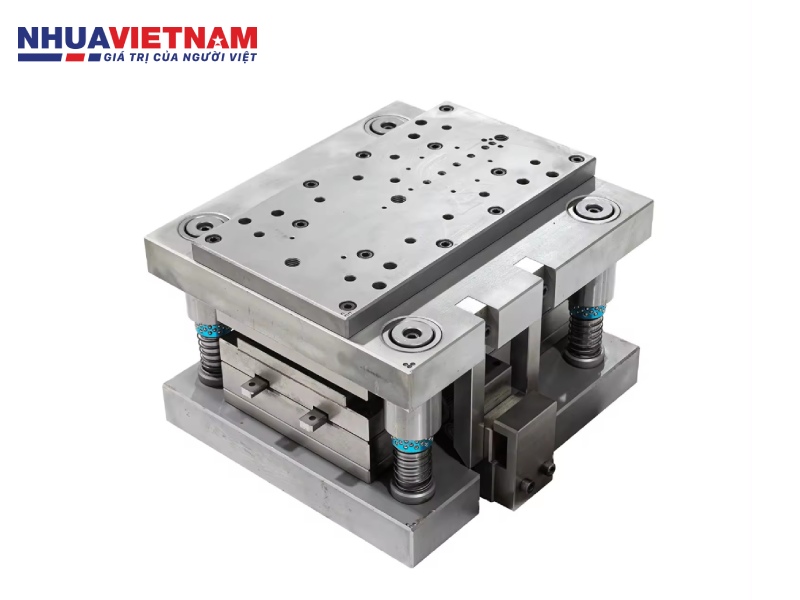

Affordable Plastic Injection Molds are a practical solution for businesses looking to optimize initial investment while maintaining consistent production quality. Unlike high-end molds with lifespans of millions of cycles, budget molds are tailored for mid-volume production within short to medium terms—ideal for OEM projects, market testing, or applications with moderate precision requirements.

Market Shifts Toward Affordable Molding Solutions

As global competition intensifies, many manufacturers in Vietnam are adopting cost-efficient molds to enhance flexibility and reduce capital expenditure. This trend is particularly evident in FMCG, plastic electronic components, household items, and packaging sectors.

Enterprises increasingly favor mold solutions with lifespans of 100,000 to 300,000 shots—sufficient for one to two product cycles—before redesigning to match market shifts. The surge in OEM/ODM demand from international markets also heightens the need for budget-friendly molds that still meet ISO, RoHS, or CE standards, driving a dual requirement for affordability and quality assurance.

Many businesses are shifting toward affordable plastic injection molds as a cost-saving strategy.

Popular Low-Cost Mold Types

Two-plate molds

Two-plate molds are the most common due to their simple structure, lower machining cost, and ease of maintenance—suitable for basic components without sliders or complex ejection systems.

Three-plate molds

Three-plate molds offer a more refined solution by separating the runner system from the product cavity, ideal for aesthetic-focused parts. Mold types such as those with sliders, thin-wall designs, or hot runners can also be optimized into budget versions by adjusting cavity count, switching core materials, or simplifying auxiliary components.

It is essential that businesses collaborate closely with mold manufacturers to ensure the selected mold structure aligns with product volume and lifecycle, instead of basing decisions solely on unit pricing.

Is an Affordable Mold the Right Investment?

For startups or businesses expanding into plastic injection molding, affordable molds are not a stopgap solution—but a calculated investment strategy.

Enterprises should begin with cost-efficient molds single or dual-cavity molds for pilot runs, prioritize quick-change structures to reduce maintenance downtime, and choose suppliers offering strong technical support and clear warranty policies.

Partner evaluation should go beyond quotations and include quality management systems, after-sales service protocols, and transparency in all terms. Nhua Viet Nam has advised numerous SMEs in this segment, particularly for domestic and export-oriented orders.

Choosing a supplier without sufficient technical expertise can result in significant mold inaccuracies.

Avoiding Common Pitfalls

Some businesses mistakenly cost-efficient molds equate “affordable” with “lowest cost,” selecting underqualified suppliers—resulting in mold misalignment, core jamming, or runner blockage after limited cycles.

Others overlook after-sales conditions, leaving them exposed when technical issues arise early in production. A mismatch between mold cost and expected durability or precision is also common.

To minimize these risks, it’s crucial to work with experienced partners capable of providing technical simulations, proactive consultations, and strict QC before delivery.

Selecting a supplier lacking technical competence can lead to significant mold deviations.

Nhua Viet Nam’s Commitment

We understand that every mold investment directly impacts your margins and production planning. That’s why, beyond manufacturing, Nhua Viet Nam works with clients to optimize mold design based on budget, technical requirements, product lifecycle, and supply chain objectives.

Our philosophy is not to lower prices by cutting quality—but to engineer smarter designs, streamline processes, and ensure dependable production. With long-term warranty programs, scheduled maintenance, cost-efficient molds and continuous product improvement support, we help clients maintain stable operations and cost control throughout their projects.

Conclusion

Affordable Plastic Injection Molds deliver speed, cost efficiency, and flexibility—especially when deployed with strategic intent. The right partner ensures you don’t trade off technical reliability for price.

NHUA VIET NAM is proud to offer a full-package solution with strong engineering, modern facilities, and transparent post-sale support. If you're exploring cost-effective mold options without compromising performance, we’re ready to support.

Contact Information

- Hotline: +84 886 723 131

- Email: info@vnplastic.vn

- Address: No. 56, Street 455, Group 4, Hoi Thanh Hamlet, Binh My Commune, Ho Chi Minh City.