In today’s fast-paced and precision-driven manufacturing landscape, custom mold manufacturing custom mold manufacturing has become a critical foundation for businesses aiming to optimize their production lines. As the first and most decisive step in injection molding or casting, mold quality directly impacts product accuracy, production efficiency, and speed to market. For companies seeking faster turnaround without compromising technical standards, custom mold manufacturing offers a strategic advantage.

What Is Custom Mold Manufacturing?

Custom mold manufacturing is the process of designing and fabricating molds specifically tailored to the requirements of each product—be it plastic, metal, or rubber. By producing molds based on detailed technical drawings, businesses can fully control design features, surface structure, material choices, and dimensional tolerances. This ensures the final mold is perfectly aligned with production needs, minimizes defect rates, streamlines operations, and reduces time-to-market.

The mold must ensure high precision.

Why Should Businesses Invest in Custom Molds?

Unlike standard molds custom mold manufacturing , custom-designed molds are engineered for exact compatibility with the enterprise’s existing production system. In industries where precision tolerances below 0.01mm or complex shapes are required, generic molds often lead to higher error rates, longer adjustment times, and increased operational costs.

Custom molds, on the other hand, are optimized for material efficiency, machine compatibility, and repeated performance across millions of cycles custom mold manufacturing . They also allow better control over mechanical standards such as load resistance, wear tolerance, and heat dissipation—enabling product innovation and faster adaptation to new technologies.

Custom mold manufacturing enables businesses to maintain strict control over mechanical standards.

Our Process at Nhua Viet Nam

At Nhua Viet Nam, we implement a strict multi-step process custom mold manufacturing to ensure every mold meets our clients' exact requirements:

- Requirement Analysis: Our engineers review technical drawings and advise on optimal mold structure, materials, compatible machines, and expected mold life.

- 3D Design & Flow Simulation: CAD/CAM software is used to simulate plastic flow, air release, and thermal deformation to optimize the design before machining.

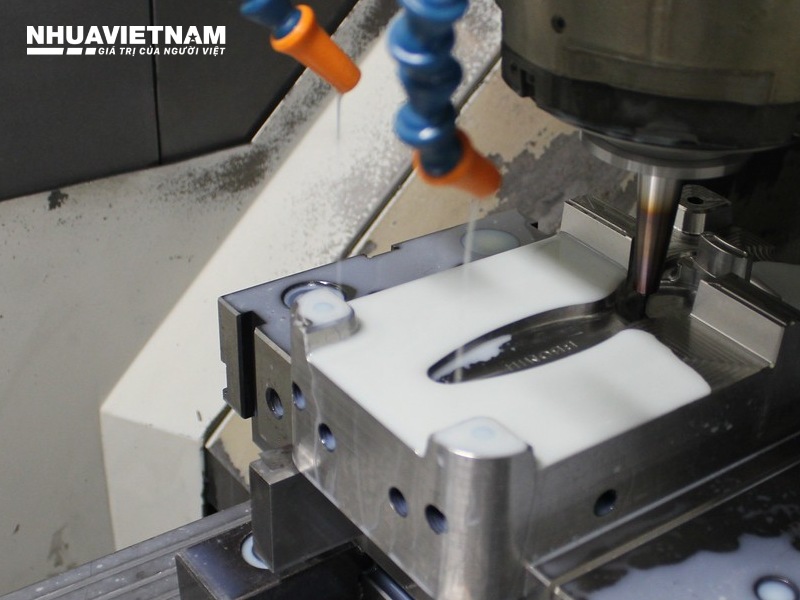

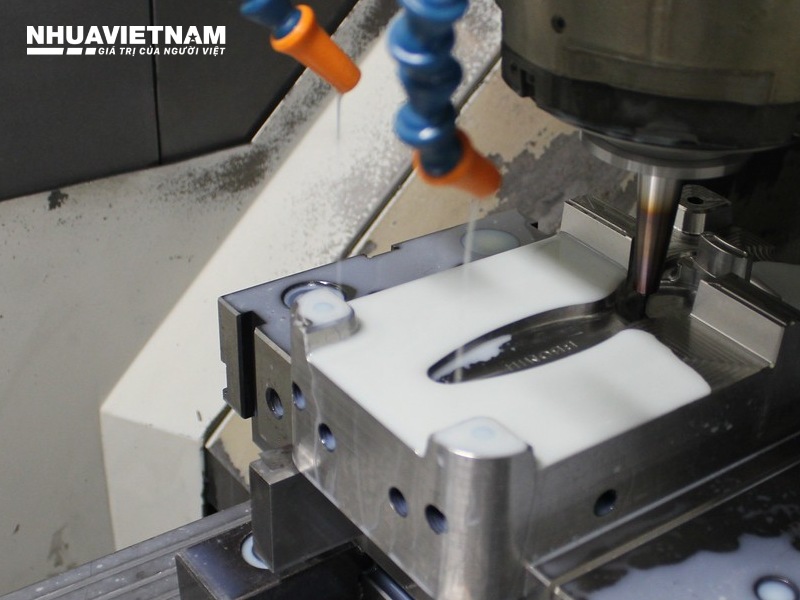

- CNC & EDM Precision Machining: High-precision 5-axis CNC centers, EDM systems, and wire-cutting machines ensure all mold components meet tight tolerances.

- Assembly & Testing: Molds are assembled in clean rooms, tested on real machines for pressure, temperature, and cycle time, and adjusted before delivery.

- Delivery & After-sales Support: We provide structural warranties, spare parts, and full technical support during the mold’s lifecycle.

Your business will receive expert consultation on optimal mold structure tailored to your production goals.

Why Choose Nhua Viet Nam?

With nearly two decades of experience in technical plastic manufacturing, Nhua Viet Nam is trusted by OEM clients across the US, Europe, and Asia. Our competitive edge lies in three pillars: speed, capacity, and quality.

- Faster Turnaround: Our smart scheduling and 24/7 operations enable delivery 5–10 days ahead of market standards, ideal for time-sensitive OEM orders.

- High-volume Production: Our factory in Ho Chi Minh City can handle multiple mold projects concurrently, supporting plastic output up to 5 million units/month.

- Strict Quality Control: Each mold undergoes thorough inspections from imported steel hardness to final sample testing—ensuring reliable mechanical performance.

Conclusion

Custom mold manufacturing is not a short-term cost—it's a long-term investment in product quality, supply chain efficiency, and business growth. In today’s competitive market, only companies that standardize from the tooling stage can accelerate product launches, control costs, and scale with confidence.

Contact NHUA VIET NAM today for expert consultation and a tailored quote for your next mold project.

Contact Information

- Hotline: +84 886 723 131

- Email: info@vnplastic.vn

- Address: No. 56, Street 455, Group 4, Hoi Thanh Hamlet, Binh My Commune, Ho Chi Minh City.