In modern manufacturing, mold manufacturing making plays a pivotal role as the foundation for producing high-quality plastic products that meet diverse market demands. By combining advanced technology with a team of seasoned experts, NHUA VIET NAM proudly delivers optimized mold-making solutions that ensure accuracy, aesthetic excellence, and cost-efficiency — making us a trusted partner for businesses of all sizes.

What is a Mold?

A mold is a specialized metal tool designed to shape plastic products through molding or injection processes. Each mold is meticulously crafted for a specific production cycle — whether for one-off prototypes or mass production. At Vina Plastic, we tailor the size and structure of every mold to match the desired shape, dimensions, quality, and quantity of your plastic products, ensuring precision and consistency throughout the manufacturing process.

Each mold is meticulously crafted to serve a specific production cycle.

Applications of Molds

Manufacturing Industrial Products

Precision mold making enables businesses to produce millions of identical parts with consistent quality and high dimensional accuracy. In the automotive and aerospace industries, molds are used to manufacture components such as interior trims, outer shells, and engine parts — delivering optimal durability, lightweight performance, and safety. Likewise, in electronics and home appliance sectors, precise molds are essential for creating device casings like those of phones, TVs, refrigerators, and washing machines — ensuring both aesthetic appeal and perfect fit.

Shaping Household and Consumer Products

Molds are an integral part of everyday life through the production of consumer goods. Common household items such as bowls, plates, cups, plastic bottles, and food containers are manufactured using injection molding technology, offering convenience and durability. Even colorful and uniquely shaped children’s toys are made from molds, ensuring consistent quality, safety, and appealing design.

Applications in Healthcare and Specialized Industries

In the medical field, molds are used to produce items such as syringes, test tubes, and components for medical devices, all of which require absolute precision and high levels of sterility. In specialized industries, molds enable the creation of plastic parts with unique properties — such as heat resistance, chemical durability, or custom functionalities — meeting the rigorous technical demands of niche markets.

Molds Are Applied Across Various Industries

Mold Manufacturing Service at Nhua Viet Nam

Nhua Viet Nam is proud to be a trusted partner in precision mold making and high-quality plastic production. We offer a fully integrated process — from accurate 3D design using CAD software to mold fabrication with advanced CNC machines imported from Japan. With cutting-edge technology and a team of experienced technicians, each mold we produce meets strict standards for precision, aesthetics, and technical performance.

Our commitment is to deliver optimized mold manufacturing solutions tailored to your production needs — whether for high-volume orders or specialized applications — all at competitive costs. Aiming to be your long-term partner, we ensure every mold is export-ready and built for stability and reliability across all your projects.

Plastic Mold Manufacturing Process at Nhua Viet Nam

Step 1: Creating the design drawing based on client requirements

Our mold manufacturing process begins with detailed design drawings tailored to your specific requirements. Our expert team will work closely with you to ensure the drawing is not only technically accurate but also aligned with your vision and objectives. This step forms a crucial foundation for the entire production process.

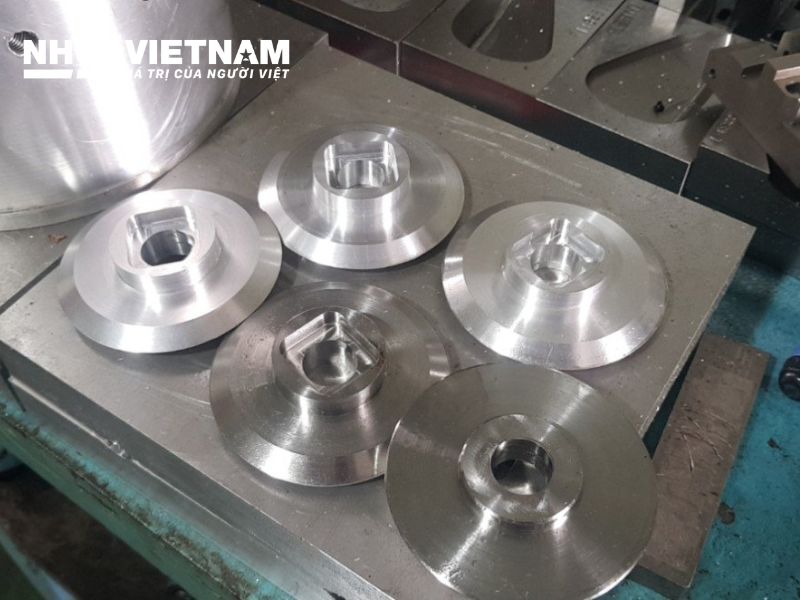

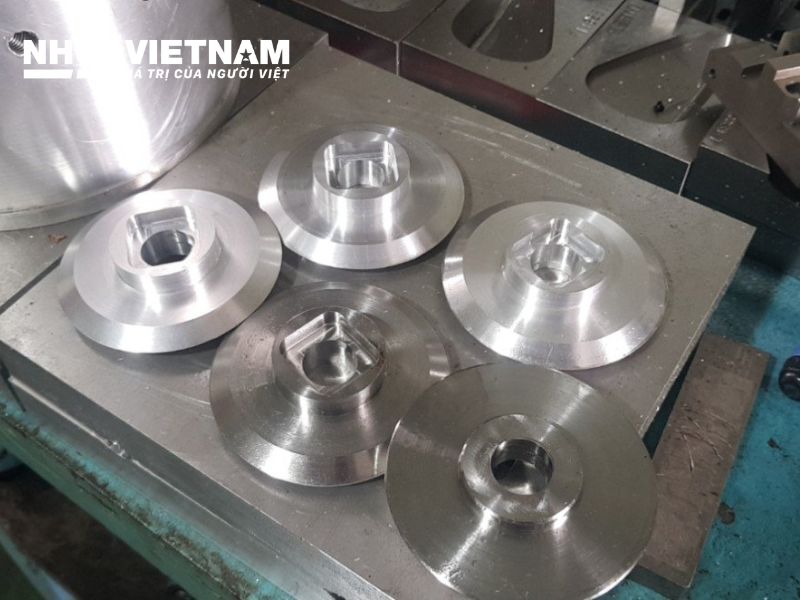

Step 2: Designing and fabricating the plastic mold

Once the drawing is approved, we proceed with designing and fabricating the plastic mold based on the sample or approved drawing. By leveraging advanced technology and a highly skilled technical team, each mold is meticulously crafted to ensure exceptional precision and consistent quality, fully prepared for the subsequent stages of production.

Step 3: Testing and finalizing the mold

In the final stage, we conduct thorough mold testing, inspecting product quality and making refinements as needed. This ensures the mold operates flawlessly and delivers final products that meet the highest standards, ready for mass production.

Technology Applications in Mold Manufacturing at Nhua Viet Nam

CAD Software for Mold Design

CAD (Computer-Aided Design) software is a vital tool that allows our design team to create accurate 2D and 3D mold models. At Nhua Viet Nam, we use CAD to build and refine mold designs before fabrication, ensuring high precision and compatibility with real-world production needs. This technology streamlines the design phase, minimizes errors, and significantly shortens development time.

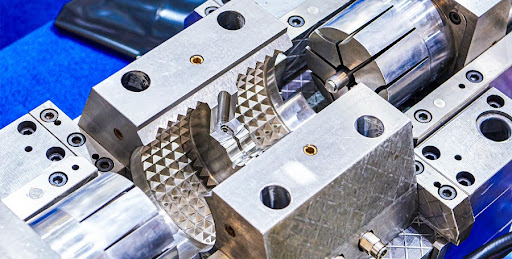

CNC Technology in Mold Machining

CNC machines — capable of high-precision cutting, turning, milling, and laser processing — are indispensable in our mold manufacturing process. By integrating CNC with other advanced technologies, we operate a high-efficiency production system that delivers exceptional finishing quality and aesthetic detail. CNC remains the leading mechanical processing technology, offering unmatched precision and reliability in modern mold fabrication.

CNC Technology Ensures High-Quality Mold Finishing

Customer Support Policy at Nhua Viet Nam

50% Mold Value Offset for Product Orders

To support our clients, we offer a cost-saving policy: 50% of the mold value will be offset against the cost of plastic products when manufactured at our facility. This reduces your upfront investment, allowing you to focus on developing high-quality products with greater financial flexibility.

100% Mold Value Offset with Order Commitment

For customers who commit to minimum order volumes and maintain stable long-term cooperation, we provide a full 100% mold value offset into the product cost — helping you scale efficiently with no tooling burden.

Capabilities and Equipment in Mold Manufacturing

Advanced Investment in 3D Design Technology

We make significant investments in both advanced hardware and software, with a strong focus on 3D design environments. This allows us to create accurate and intuitive mold models, capable of fulfilling even the most complex design requirements and ensuring quality from the very beginning.

CNC Machines Imported from Japan

Our production uses high-precision CNC machines imported directly from Japan. These machines deliver exceptional accuracy and finishing quality, meeting even the most demanding mold specifications for high-efficiency production.

End-to-End Production Process

Our integrated closed-loop process—from mold design to final product delivery—ensures consistent quality control, streamlined timelines, and top-tier results for our clients.

Commitment to Quality and Value

Nhua Viet Nam is committed to delivering molds and plastic products that meet premium aesthetic and technical standards at competitive prices. We prioritize customer satisfaction and are always ready to meet your needs with reliable, value-driven solutions.

Conclusion

Precision mold is where engineering meets creativity to bring internationally standardized products to life. At NHUA VIET NAM , we are committed to accompanying our clients through every step — from design to production — delivering lasting value and complete satisfaction. Let us turn your ideas into reality with reliable, high-quality, and efficient mold-making solutions tailored to your needs.

Contact information

- Address: Số 56 đường 455, tổ 4, ấp Hội Thạnh, xã Bình Mỹ, TP.HCM

- Hotline: 0886 723 131

- Email: info@vnplastic.vn