Among today’s popular mold types, 2-plate mold mold stands out as an efficient solution for producing high-precision, high-volume parts with simple designs. This article explains its working principle, structure, and technical standards that manufacturers should consider when selecting and operating this mold type.

What Is a 2-Plate Injection Mold?

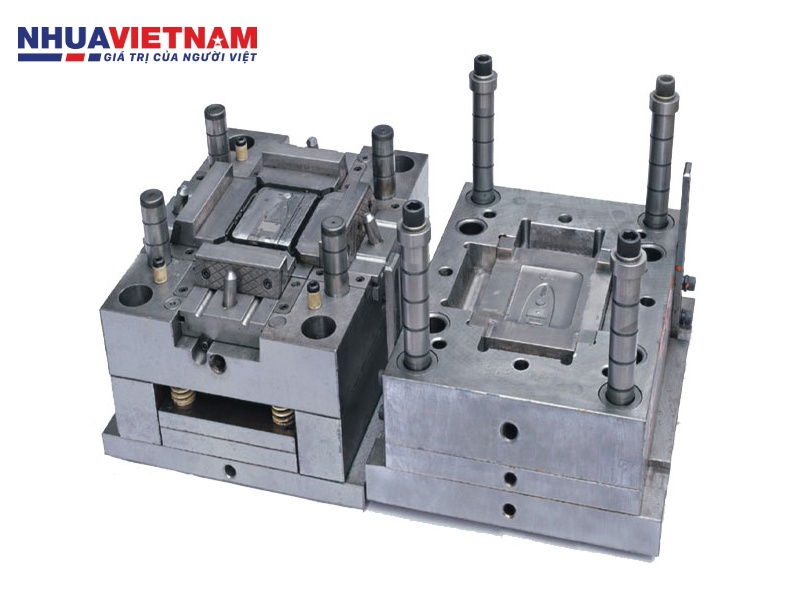

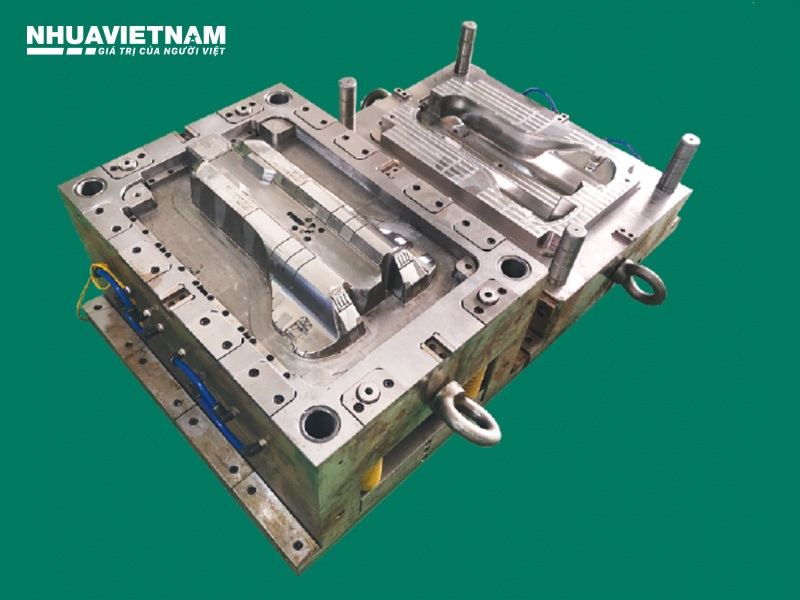

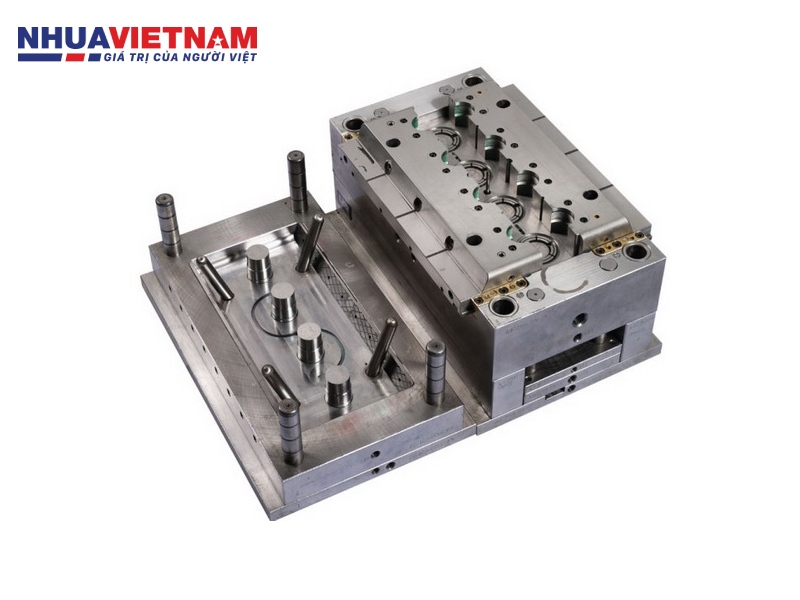

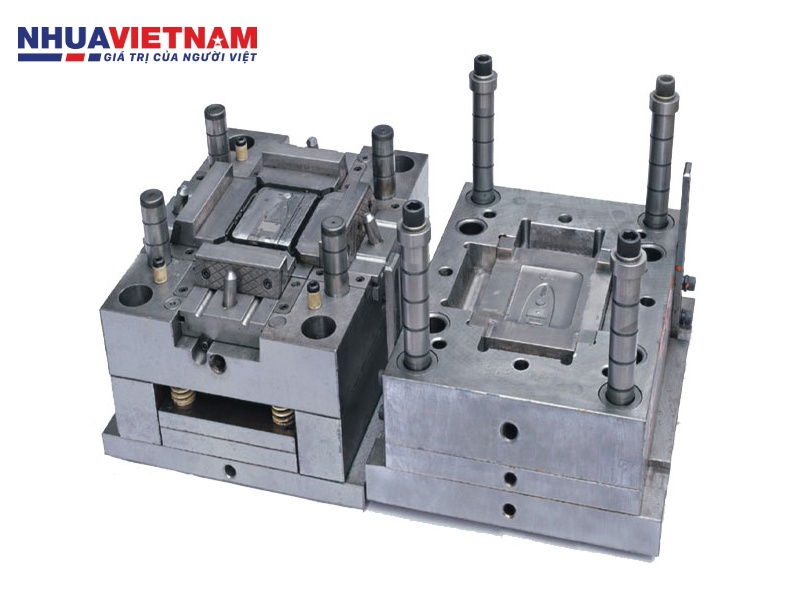

A 2-plate mold consists of two main components: a fixed plate (attached to the stationary platen) and a moving plate (connected to the moving platen). During each cycle, molten plastic is injected into the cavity between these plates, cooled, and then ejected as a finished part.

Thanks to its simple construction, this mold is widely used for products without undercuts—such as bottle caps, electronic housings, and household items. Its ease of operation and cost efficiency make it ideal for large-scale production lines.

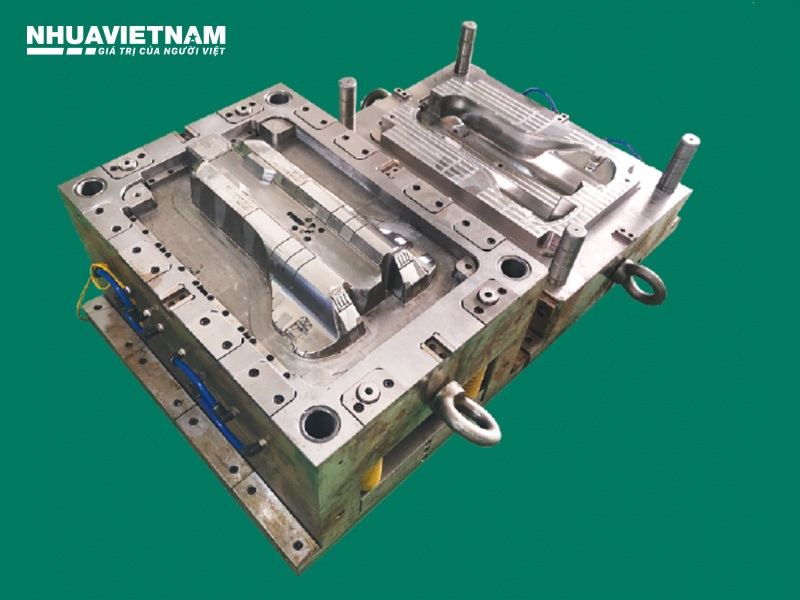

A 2-plate injection mold consists of a fixed plate and a moving plate.

How It Works

A 2-plate mold operates through a repeatable 5-stage mechanical cycle. First, the mold closes tightly under clamp force. The injection nozzle aligns with the sprue bushing to deliver plastic through the main runner.

Ở bước thứ hai – giai đoạn điền đầy, nhựa sau khi được hóa lỏng trong xy lanh cấp liệu sẽ được bơm qua bạc cuống phun, dẫn theo runner (kênh dẫn chính), phân bố vào từng lòng khuôn để tạo hình sản phẩm. Sau khi khuôn đã được điền đầy, quá trình làm nguội và định hình bắt đầu.

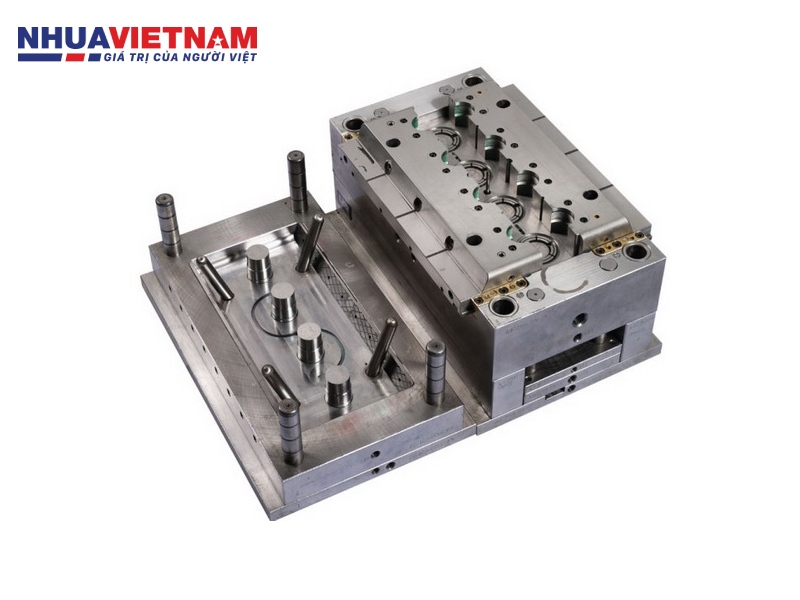

The 2-plate injection mold operates based on a cyclical mechanical principle.

Nhờ hệ thống kênh giải nhiệt được bố trí dọc theo các tấm khuôn, dòng nước làm mát sẽ hấp thụ nhiệt từ nhựa, giúp vật liệu đông đặc và định hình chính xác. Khi sản phẩm đủ nguội, khuôn được mở ra, tách hai nửa lòng khuôn. Hệ thống đẩy được kích hoạt: xilanh máy ép tác dụng lực lên tấm đẩy, đẩy ty lói di chuyển và tách sản phẩm ra khỏi lòng khuôn. Sau khi sản phẩm được lói ra ngoài, hệ thống đẩy sẽ được hồi về một phần nhờ lực lò xo.

Trong bước cuối, khi khuôn tiếp tục đóng lại, chốt hồi sẽ tác động lên các tấm đẩy, đưa toàn bộ hệ thống đẩy về vị trí ban đầu, sẵn sàng cho chu kỳ ép tiếp theo. Quá trình này lặp lại liên tục với tốc độ cao, đảm bảo tính ổn định trong sản xuất hàng loạt.

Key Advantages of the 2-Plate Mold

A 2-plate mold the simple structure reduces initial machining cost and allows faster cycle times than 3-plate or core-pulling molds. It’s easy to maintain and well-suited for automation, making it a smart choice for medium to large manufacturing plants.

For businesses seeking stable production with minimal overhead, 2-plate molds offer excellent cost control and productivity.

2-plate injection molds are easier to maintain compared to 3-plate molds.

Standard Structure

A standard 2-plate mold includes: cavity plate, core plate, guide pins and bushings, runner system, gates, cooling channels, and an ejector system integrated into the moving half. This structure supports long production runs while maintaining product consistency.

Ideal Applications

A 2-plate mold are commonly used in the production of consumer goods, casings, motorcycle and automotive parts, electrical components, and industrial packaging. Products with simple shapes and no internal undercuts are best suited for this mold type. Export products also favor it for its speed and efficiency.

Quality Standards

A qualified 2-plate mold must meet strict standards for dimensional accuracy, mechanical strength, thermal resistance, and durability. Common mold steels include SKD61, P20, and H13—often heat-treated to extend mold life.

Smooth ejector performance and effective cooling are essential to avoid defects like warping or incomplete ejection. That’s why choosing a skilled mold maker with modern equipment is key to final product quality.

2-Plate vs. 3-Plate Molds

While 3-plate molds offer better gate control and aesthetics for complex parts, they are more expensive and slower to cycle.

In contrast, 2-plate mold are faster and more cost-effective—ideal for simpler, high-volume parts. Ultimately, mold selection depends on product design, budget, and production goals.

Conclusion

A 2-plate mold is a dependable solution. Its straightforward design and proven reliability make it a staple in industrial manufacturing. Understanding how it works and what standards matter can help businesses maximize mold efficiency and maintain long-term product quality.

Contact Information

- Hotline: +84 886 723 131

- Email: info@vnplastic.vn

- Address: No. 56, Street 455, Group 4, Hoi Thanh Hamlet, Binh My Commune, Ho Chi Minh City.