Looking for a custom technical plastics processing partner that guarantees both precision and production speed? In today’s industrial landscape, technical plastic components demand increasingly high standards in material quality, durability, and optimized design. NHUA VIET NAM is proud to be a trusted manufacturing partner for hundreds of businesses both domestically and internationally. With robust production capabilities, strict quality control processes, and a highly skilled technical team, we are ready to deliver reliable, high-performance plastic solutions tailored to your needs.

What is Technical Plastic?

Technical plastic refers to a class of specially engineered plastic materials that offer superior properties compared to standard plastics, including high mechanical strength, chemical resistance, optical clarity, and heat tolerance.

Unlike conventional plastics with fixed compositions, technical plastics are customized based on the specific technical requirements of the final product. This flexibility allows them to meet stringent industry standards and perform reliably across a wide range of applications — from electronic components and automotive parts to medical devices — delivering exceptional durability, precision, and performance.

Applications of Technical Plastics

Automotive Industry

In the automotive industry, technical plastics are essential for creating housings for computers, smartphones, and other electronic devices. Acrylonitrile Butadiene Styrene (ABS) is the most widely used plastic in this field due to its high impact resistance, attractive finish, and easy moldability, meeting both technical and modern design requirements.

Electronics Industry

Technical plastics are essential for creating housings for computers, smartphones, and other electronic devices. Acrylonitrile Butadiene Styrene (ABS) is the most widely used plastic in this field due to its high impact resistance, attractive finish, and easy moldability, meeting both technical and modern design requirements.

Food Packaging Industry

In food packaging, technical plastics are used to produce water bottles, food containers, and plastic films. Polyethylene Terephthalate (PET) stands out for its high clarity, excellent impact resistance, and odor-retaining properties, ensuring food safety and quality.

Construction Industry

Technical plastics are applied in making water pipes, windows, and doors. Polyvinyl Chloride (PVC) is a preferred material for pipe production due to its exceptional corrosion resistance, ease of installation, and cost-effectiveness, supporting sustainable construction solutions.

Medical Industry

In healthcare, technical plastics are used in products like syringes, IV tubes, and surgical tools. Polypropylene (PP) is favored for its chemical resistance, non-toxicity, and high stability — ensuring safety and reliability in medical applications.

Other Applications

Technical plastics also serve in the aerospace industry for high-precision, durable, and lightweight parts. Beyond that, they're used in mold making for fashion items, engineering plastic boxes, electrical insulation parts, electronic circuit boards, anti-static sheets, waterproof partitions, and even for signage, interior design, and construction — offering versatile solutions across many sectors.

Key Factors to Consider in Technical Plastic Processing

Choosing the Right Material

Each type of technical plastic has distinct properties suited to specific applications such as automotive, electronics, or medical devices. Selecting the correct material is the first and most critical step to ensure strength, heat resistance, and mechanical performance meet required standards.

Precision Mold Design

The mold is the core of plastic processing, directly impacting product shape and quality. A well-designed mold must ensure tight sealing and incorporate an effective cooling system to deliver flawless finishes and minimize defects during production.

Temperature Control

Temperature plays a major role in processing quality for technical plastics. Technicians must precisely regulate mold temperature, melt temperature, and ambient conditions. Stable temperatures help preserve material properties and prevent defects like warping or shrinkage.

Injection Pressure Adjustment

Injection pressure should be fine-tuned according to the plastic type and product shape. Excessive pressure may cause internal stress or part failure, while insufficient pressure can lead to incomplete filling or defects. Optimizing pressure ensures product consistency and dimensional accuracy.

Controlling Injection Speed

The injection speed must be carefully managed to ensure smooth plastic flow, completely filling the mold without air traps or surface imperfections. Proper speed delivers uniform products with high surface quality.

Proper Cooling Time

Cooling time determines the product’s final shape and hardness. Insufficient cooling may result in deformation or weak structure. Adequate cooling allows the plastic to solidify fully, ensuring stability and durability.

Post-Processing Handling

After molding, products often require additional finishing such as trimming, polishing, or coating to meet both aesthetic and technical standards. These steps enhance appearance and ensure market-ready quality.

Dust and Environmental Control

A clean, temperature-controlled environment reduces contamination risks and protects machinery. Maintaining air quality and consistent temperature is essential for product integrity and minimizing process variation.

Quality Control and Preventive Maintenance

To address challenges like inconsistent materials, equipment issues, or contamination, Nhua Viet Nam implements strict quality control systems and preventive maintenance. With modern technologies and clean manufacturing practices, we ensure every product meets the highest standards.

Technical Plastic Processing Service at Nhua Viet Nam

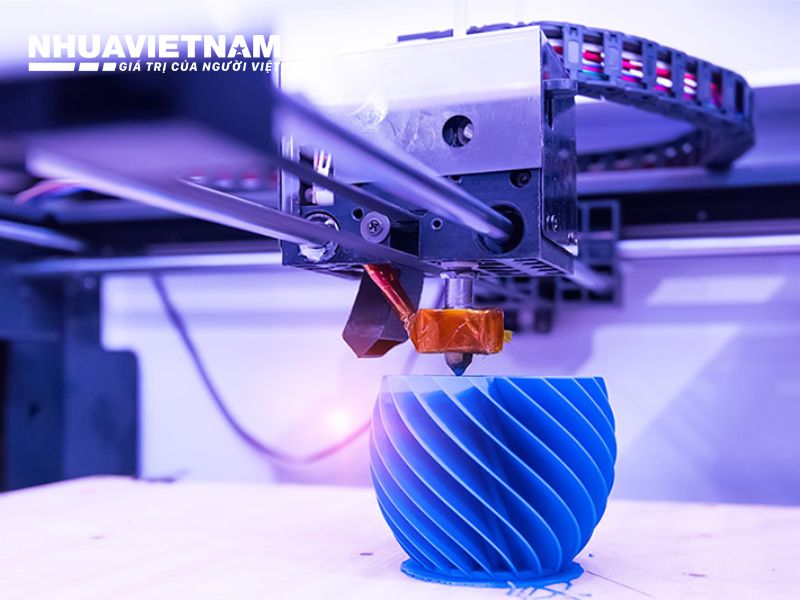

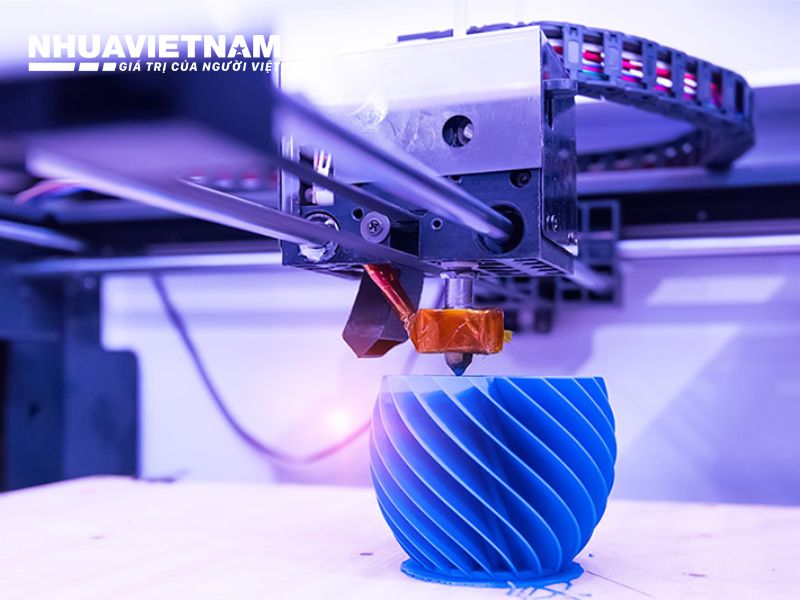

Nhua Viet Nam offers professional technical plastic processing services for industries such as automotive, electronics, healthcare, packaging, and construction. We work with high-quality engineering plastics like POM, ABS, PC, PP, PA, and PET-G — carefully selected to meet specific technical requirements. Through a fully integrated workflow — from 3D design using CAD software to mold fabrication on CNC machines imported from Japan — we ensure every product meets high precision, outstanding aesthetics, and export-grade standards.

We accept both OEM and ODM orders and deliver quickly thanks to advanced injection molding technology, with strict control over temperature, pressure, and injection speed. Every production batch is thoroughly inspected, from raw material to final product. Contact Nhua Viet Nam today for expert consultation and a detailed quotation!

Conclusion

plastic processing engineering plastic processing, Nhua Viet Nam is committed to delivering efficient production solutions with consistent quality and optimized costs for every project. Whether you require large-scale production or custom-designed orders, our advanced machinery and streamlined workflow allow us to respond quickly and reliably. Contact NHUA VIET NAM today for expert technical consultation and a detailed quotation tailored to your specific needs.

Contact information

- Address: Số 56 đường 455, tổ 4, ấp Hội Thạnh, xã Bình Mỹ, TP.HCM

- Hotline: 0886 723 131

- Email: info@vnplastic.vn